Osa Warehouse

Management

Control your entire network to easily meet complex demands.

Unify Warehouse Operations

End-to-end visibility, advanced automation, and actionable insights.

AI-Powered Efficiency.

Digital Warehousing.

Cloud-based WMS solutions for

tomorrow's challenges.

In today’s fast-paced world, evolving business and consumer demands require more than just a traditional WMS—especially for omnichannel fulfillment.

Osa Warehouse Management System is designed to optimize efficiency, enhance accuracy, save time, and reduce costs across your warehouse operations.

Built-In ROI.

WMS to optimize operations, reduce costs, and seize opportunities.

Real-Time Inventory Tracking

Gain 360-degree inventory visibility across all locations with real-time updates to ensure stock accuracy and minimize discrepancies.

Seamless System Integration

Integrate effortlessly with ERP, OMS, TMS, and e-commerce platforms to streamline your supply chain and unify operations.

Automated Workflows

Reduce manual errors and accelerate processes with automated picking, packing, and receiving workflows designed for operational efficiency.

Advanced Reporting & Analytics

Leverage on-demand reports and predictive analytics to make data-driven decisions and forecast inventory needs.

Customizable Configurations

Adapt the platform to your unique business requirements with flexible features and tailored integrations.

Break Data Silos with a Single Source of Truth.

Unified insights for smarter warehouse management.

Break free from fragmented systems and empower your team with a single source of truth for all warehouse operations. Centralize your operations and transform your warehouse with a cloud-based Warehouse Management System that delivers unified insights for smarter decision-making.

How Can Osa Solve Your Supply Chain Chaos?

Learn how our cloud-based WMS offers complete warehouse functionality and fulfillment management.

Centralized Intelligence

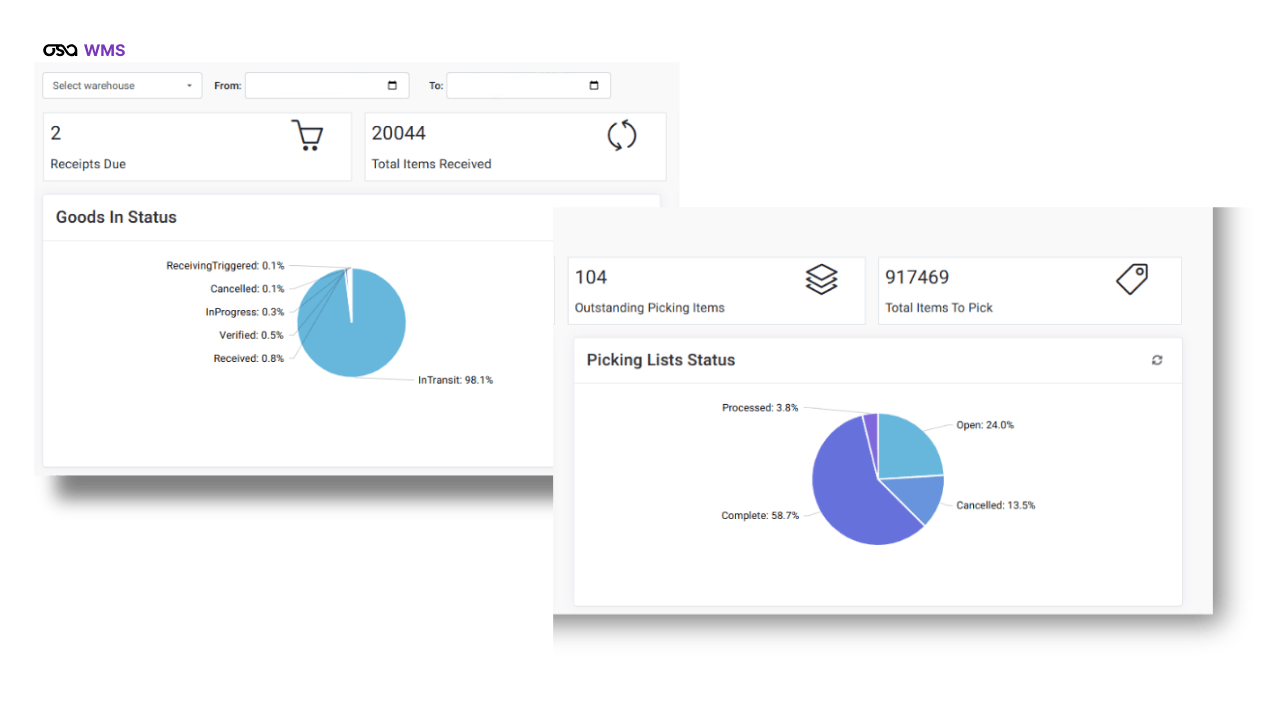

Get AI-driven insights through a real-time, single dashboard for manual and robotics operations at both the executive and transactional level.

Enhanced Visibility

Get comprehensive operational insights, from high-level overviews to individual tasks, including past and future performance.

Dynamic Workflows

Utilize a unified WMS solution to speed up inbound replenishment and outbound fulfillment to save on costs and errors.

Tailored for Excellence

Warehouse Managers and Logistics leaders can create warehouse operations to fit their business and customer needs.

Reduced Labor Costs

Reduce administrative burden by removing manual tasks to allow staff to focus on value-added activities.

Priority Performance

Adjust tasks and priorities, such as carrier appointment schedules, for escalation or de-escalation.

4 Weeks to Revenue

Achieve faster time-to-value omnichannel operations by speeding up onboarding for robotics and versatile API integrations.

Optimized for Warehouse Leadership

Eliminate silos, stay connected, and confidently unlock the full potential of your logistics operations.

Osa Warehouse Management Benefits

Inventory Forecasting

Accurately forecast inventory to minimize stockouts and overstocks across all warehouses.

Omnichannel Selling

Manage multichannel operations, pricing, inventory, replenishments, revenue, and more.

Automate Operations

Increase efficiencies and speed up warehouse processes by up to 4X with automated workflows.

Robotics Integration

Integrate with robotics systems for fully automated warehouse operations and improved performance.

Wave Management

Quickly fulfill product allocations with a scalable wave management tool to reduce workloads.

Returns Management

Powerful returns authorization management including RMA for financial processing.

Value Added Services

Manage complex e-commerce value-added service requirements, including service billing.

Carrier Integrations

Preset cost-effective parcel shipping, rate shopping, sortation, and label generation.

FAQs

What is a warehouse management system?

-

A WMS is:

A Warehouse Management System, or WMS, is a software solution used to support and manage the day-to-day operations of warehouses or distribution centers. WMS software facilitates efficiency and optimizes operations—from receiving to storage—including picking, packing, and shipping. WMS technology helps brands, retailers, and third-party logistics (3PL) warehouses collaborate processes, drive greater visibility and transparency, and enhance overall supply chain management and performance.

What are the types warehouse management systems?

-

WMS types include:

WMS can be categorized into four commonly used systems: standalone System, ERP Inventory, Cloud-Based, and Supply Chain module.

Standalone WMS: Standalone systems are dedicated systems focused solely on limited warehouse management functions. They work for smaller warehouse operations that do not want to integrate with outside technologies. Standalone systems offer basic functionality, including picking, packaging, and shipping.

ERP Inventory Modules: ERP or Enterprise Resource Planning systems can help expand supply chain operations for brands and 3PLs. Core warehouse functionality is not usually included but ERP systems can integrate with most cloud-based WMS software. These systems work best for enterprise organizations as implementations can be long and system costs are more expensive.

Cloud-Based WMS: Cloud-based WMS offers complete warehouse functionality that is accessible online, offering flexibility and scalability. These systems work well for e-commerce and omnichannel businesses looking to implement integrations quickly. Many cloud-based systems, or SaaS (Software as a Service), offer increased flexibility, data security, and scalability and can be used by 3PLs with limited IT resources.

Supply Chain Modules: Supply chain modules are parts of supply chain management software or platform—enhancing overall supply chain efficiency. For example, a cloud-based WMS may also be a part of collaborative technology with modules to help with integrations, order management, unified commerce, fulfillment, or last mile.

What type of WMS does Osa offer?

-

Key WMS features include:

The Osa Collaborative Visibility Platform offers a cloud-based WMS accessed through a web interface. Any data entry device supported by the browser is supported. A fully functional middle system API layer allows for direct integration into system processes, automation, and robotics systems. The platform also includes a fully functional middleware system to manage integrations between other supply chain systems and end-user customized automation flows through javascript coding.

Key capabilities include:- Inventory Tracking

- Process Management

- Pick, Pack, Ship

- Inbound and Outbound Order Processing

- Appointment Scheduling

- Work Order Management

- Operations Tracking and Tasking

- And more

Who uses warehouse management system software?

-

WMS is used by:

Warehouse Management System (WMS) software is used most commonly by distributors, e-commerce and omnichannel fulfillment centers, third-party logistics (3PLs) providers, and fourth-party logistics (4PL) networks. Almost all industries that require warehouse processes to pick, pack, and ship orders will use a WMS to optimize processes, improve accuracy, and streamline efficiencies, including integrations to marketplaces, shopping carts, or other supply chain management technologies.

For Businesses That Need More Than a WMS.

Osa Collaborative Visibility WMS.

Enhanced warehouse management to meet the complex demands of e-commerce fulfillment—and more.