5 min read

How PLM Integration and Order Management Systems Work Together to Drive Unified Commerce

![]() Osa Commerce

:

October 27, 2025

Osa Commerce

:

October 27, 2025

Discover how Product Lifecycle Management (PLM) and Order Management Systems (OMS) integration creates smarter, more connected supply chains with unified commerce, data accuracy, and real-time visibility.

The Power of Connected Commerce:

Unifying PLM and OMS

Brands, retailers, and third-party logistics (3PLs) are under pressure to synchronize product launches, maintain inventory accuracy, and deliver seamless omnichannel experiences. Success is dependent on visibility, speed, and accuracy. Yet many businesses still rely on disconnected and siloed systems to manage products, orders, and fulfillment. What they end up with is mismatched SKUs, fulfillment delays, and missed opportunities for customer satisfaction.

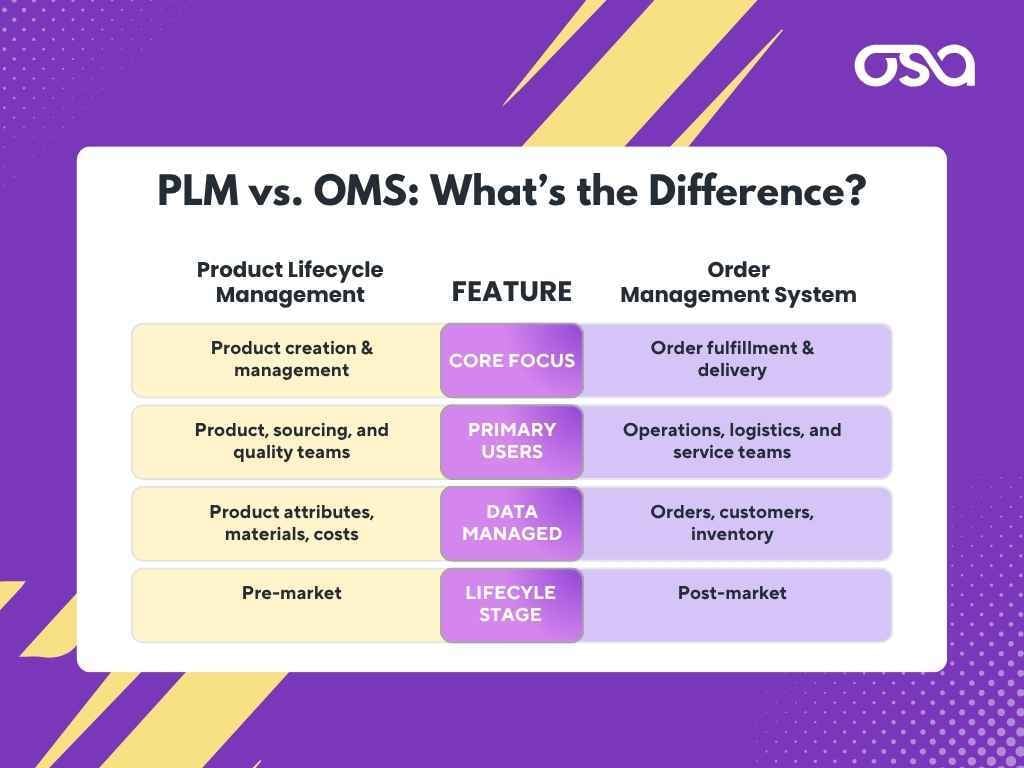

Integrating mission-critical systems is essential for companies seeking unified commerce, real-time visibility, and supply chain resilience. PLM solutions empower organizations to manage every stage of a product’s journey, from conception and design to sourcing and commercialization, ensuring data consistency and compliance. OMS, on the other hand, orchestrates the order-to-cash process, automating order capture, inventory allocation, fulfillment, and customer communication across sales channels.

Together, these systems create an ecosystem that serves as the digital backbone of modern supply chains, unifying product innovation with flawless order execution.

What is Product Lifecycle Management (PLM)?

A Product Lifecycle Management (PLM) system manages every phase of a product’s life—from concept and design to sourcing, production, and market launch.

PLM software consolidates product data, enabling teams to be united across design, sourcing, compliance, and production.

.jpg?width=1200&height=1200&name=What%20is%20PLM%20(1).jpg)

Who Uses PLM Systems:

- Manufacturers and brands that develop new products and bring them to market faster.

- Retailers that manage and expand private-label or exclusive product lines.

- Sourcing and procurement teams to coordinate and strengthen relationships with suppliers.

- Quality assurance teams that need to enforce and elevate product standards across the entire production process.

PLM ensures that the right product information flows seamlessly and consistently across the supply chain network—fueling faster innovation and fewer costly errors.

What Is an Order Management System (OMS)?

An Order Management System (OMS) handles orchestration of the entire order lifecycle. Once a product is ready to go to market, OMS coordinates and tracks orders from entry through inventory visibility and levels, fulfillment, and returns across multiple channels to ensure a seamless, consistent customer experience. This is especially important for omnichannel businesses.

An OMS ensures the right products reach the right location and the right customer as efficiently as possible.

Who Uses OMS?

- Retailers and brands that orchestrate omnichannel orders to deliver seamless customer experiences.

- 3PLs and logistics providers that optimize fulfillment operations and ensure on-time delivery.

- Customer service teams who need to track orders in real time and resolve returns efficiently.

Order Management Systems act as the orchestrator of post-sale operations and are the center of commerce operations—ensuring product availability and ultimate customer satisfaction.

Streamlining Product Data for Fast and Accurate Order Fulfillment:

PLM Integration Enhances OMS Performance

Product lifecycle management (PLM) lays the foundation for the product and establishes a single source of truth. Order management systems (OMS) keep the engine running, ensuring product and order data work together to unify the product and customer journey.

When PLM and OMS are fully integrated, product introductions and modifications flow seamlessly into the order management environment. This eliminates manual re-entry, reduces errors, and accelerates time-to-market. Brands and 3PLs can easily collaborate to launch new SKUs across multiple channels and confidently report on inventory levels, pricing, and product details that are always synchronized for fast, accurate, and customer-centric fulfillment.

- Data Synchronization: Product specs, SKUs, and attributes flow directly from PLM into OMS and up to date across every platform.

- Inventory Management: Real-time visibility across warehouses, channels, and fulfillment centers prevents overselling and out-of-stocks.

- Workflow Automation: When a product is updated in PLM, the change is reflected instantly in OMS and all sales channels, and automatically updates approvals, inventory, and fulfillment—eliminating manual bottlenecks.

- Faster Time-to-Market: New products go live faster and more accurately across ecommerce, retail, and wholesale marketplaces.

Enhancing Visibility and Collaboration Across the Supply Chain

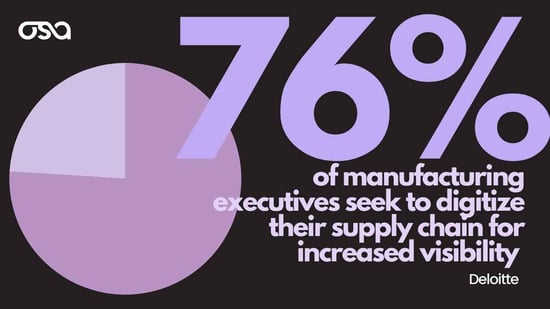

Data silos are a persistent challenge for supply chain organizations, leading to mismatched product records, inventory discrepancies, and communication breakdowns. By connecting PLM and OMS, all stakeholders—from product development to sales and fulfillment—gain collaborative visibility into product statuses, order flows, and inventory movements. This reduces the risk of fulfillment errors, overselling, and stockouts, while improving billing accuracy and compliance with service-level agreements (SLAs).

The Benefits of Connecting PLM and OMS

- Data Consistency Across Systems: Integration eliminates duplication and manual data entry, ensuring every product detail stays accurate.

- Improved Inventory Management: OMS relies on synchronized PLM data to maintain real-time stock accuracy across channels.

- Workflow Automation: Automated triggers for approvals, replenishment, and order routing reduce delays and human error.

- Omnichannel Agility: Unified product and order data ensures consistent listings, pricing, and fulfillment across all channels.

- Enhanced Customer Experience: Customers receive accurate product details, reliable availability, and faster fulfillment—building long-term loyalty.

Integrating supply chain technologies and platforms helps proactive issue resolution, supports compliance initiatives, and facilitates data-driven decision-making. In addition, automation of repetitive tasks frees up teams to focus on innovation and customer service, supporting sustainable growth and agility in a dynamic market.

Osa Zero Integration Management

quickly connects systems via API-first and EDI integrations, so brands and retailers can track product data from ideation through fulfillment. 3PLs can also use Osa Zero to provide clients with real-time insights into inventory availability and order statuses. Unified commerce and visibility also support omnichannel strategies by ensuring product and order data are consistent and unified across the supply chain.

Building a Fully Connected Technology Ecosystem

For full end-to-end supply chain intelligence, businesses should connect PLM and OMS with:

- Warehouse Management System (WMS): Tracks real-time inventory movement and storage.

- Transportation or Last Mile Systems: Optimizes delivery routing and tracking.

- Integration Management Systems: Connect systems, from ERP to marketplaces, PLM to OMS, ecommerce

platforms or demand channels to WMS for a comprehensive view of operations. - Unified Commerce Platforms: Synchronize product, pricing, and order data across digital and physical touchpoints.

With these systems working together through the Osa Unified Commerce Platform, businesses gain complete control—from product concept to customer doorstep.

Mastering Order Orchestration for Efficient Supply Chain Operations

Explore the key strategies and best practices for mastering order orchestration to enhance supply chain efficiency and optimize e-commerce and omnichannel operations.

Achieving Clarity in Supply Chain Operations

Padhu Raman, co-founder and CEO, addresses the complexities of modern ecommerce operations and emphasizes the need for unified data systems and strategic collaborations to streamline the order lifecycle.

Order Management Process: A Complete OMS Guide

Let's explore the key steps involved in the order management process and how businesses can optimize each stage to streamline operations and enhance customer satisfaction.

Future-Proofing Your Logistics Business with PLM and OMS

PLM alone may be great for product creation—but it is disconnected from the customer and order fulfillment journey. On the other side, OMS is good for fulfillment—but prone to costly errors when product data is outdated or inaccurate.

When systems don’t talk to one another, the result is data silos, inventory discrepancies, and operational inefficiencies that ripple across the supply chain.

The combined power of PLM and OMS extends far beyond data synchronization. Integrated platforms pave the way for AI-powered forecasting, predictive analytics, and advanced workflow automation—not only improving demand planning and inventory optimization but also enhancing the overall customer experience through faster, more accurate order fulfillment and proactive communication.

To fully realize the benefits, supply chain businesses need to integrate technologies like PLM, WMS, OMS, last-mile solutions, and more for a single source of truth like the Osa Unified Commerce Platform. These solutions maximize end-to-end visibility, automate fulfillment, and enable real-time, omnichannel orchestration, positioning brands, retailers, and 3PLs to thrive in the evolving world of unified commerce.

Learn Osa Commerce can help you deliver complete visibility and control as you build the foundation of a future ready supply chain.

.jpg?width=1200&height=1200&name=What%20is%20OMS%20(1).jpg)