6 min read

Supply Chain 101: Modern Supply Chain Management System Guide

Katie Dalrymple

:

November 17, 2023

Katie Dalrymple

:

November 17, 2023

.jpg)

Welcome to "Supply Chain 101", where we'll explore the ins and outs of the world of supply chain management. This journey takes us from its humble beginnings to the intricate global network it is today, and peeks into what the future holds. Whether you're a curious mind, a budding entrepreneur, or just looking to understand the fascinating world of supply chain and logistics, you're in the right place. So, grab a cup of joe, and let's start class!

The ABCs of Supply Chain Managment

First off, what is supply chain management (SCM)? In simple terms, it's all about the management of the flow of goods and services—from procurement of raw materials to the final mile delivery to the end consumer. Imagine a journey where a product starts as a raw material, such as cotton, oil, lumber, etc., that is manufactured to become inventory that ends up in your customer’s hands. The entire process, including the movement from producer to manufacturer to distributor and finally to you, the consumer, is what SCM is all about.

SCM is crucial for a multitude of reasons. It helps to reduce costs, improve efficiency, and boost customer satisfaction. A well-managed supply chain ensures that the right products are available at the right time, in the right place, and at the right cost.

The Evolution of Supply Chain Management

The history of SCM is as interesting as its functions. It has evolved from simple, local systems to a complex global network. We have seen key developments over the years, from the early adoption of railroads, roads, and maritime transport, to the monumental shift of e-commerce and omnichannel fulfillment, containerization and digitization, and the internet of things (IoT). Today, supply chains are not just about physical movements but also involve sophisticated software and technology. Let’s have a little history lesson on the industry!

The Past: Origins and Evolution

The concept of supply chain management isn't new. It dates back to the early 1900s, starting as simple, local systems before the Industrial Revolution. However, the real game-changer was the introduction of railroads in the 19th century, which transformed how goods were transported over long distances.

Early 20th Century: Trucks and Warehouses

The early 20th century saw the development of trucks and warehouses, crucial elements in modern supply chains. This era marked a shift towards greater mechanization, especially during the World Wars, which necessitated efficient movement of supplies and overall logistics.

1950s-60s: Standardization and Containerization

The mid-20th century brought about significant changes, notably standardization and containerization. These innovations streamlined shipping, reducing costs and improving efficiency. It was also during this time that the concept of supply chain management began to take shape.

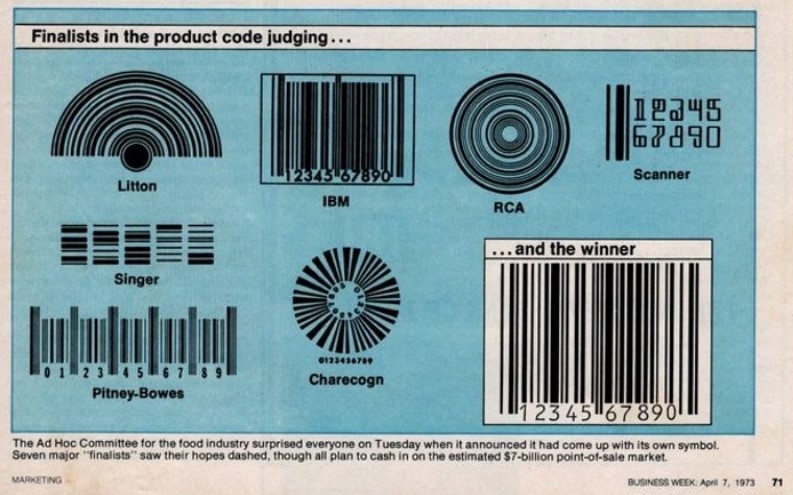

1960s-70s: Computerization and Barcodes

The advent of computerization and barcodes in the 1960s and 70s marked another major shift. This technology enabled better tracking and management of goods, paving the way for more sophisticated supply chain systems. It also paved the way for the Warehouse Management Systems (WMS) with the first real-time software created by J.C. Penney in 1975.

1980s-90s: The Digital Revolution

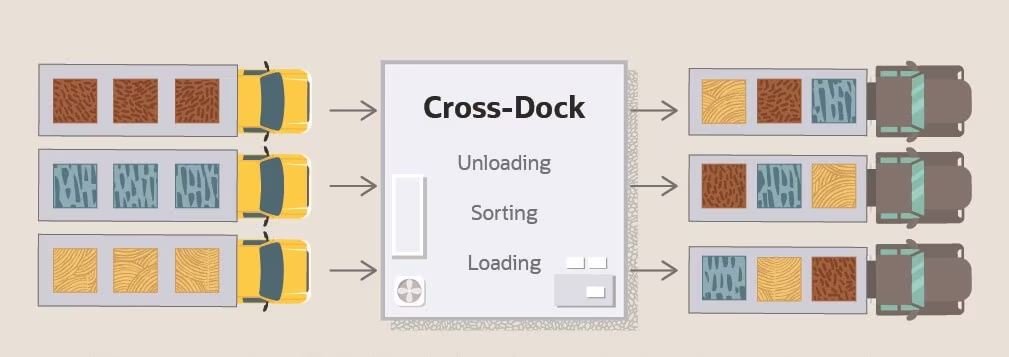

As supply chain management continued to grow alongside the economy, the need to reduce costs and time saw the first cross docking system, created by Walmart in 1988. This boom continued throughout the 90s as technology and innovation paved the way for Enterprise Resource Planning (ERP) systems helping brands and retailers manage logistics.

The Present: A Complex Global Network

Today, supply chains are global and incredibly complex—and largely managed from the cloud. They involve a network of suppliers, manufacturers, distributors, retailers, and customers, all intricately connected. Key processes include procurement, transformation, distribution, inventory management, warehousing, transportation, and now trend forecasting. Connected through a series of integrations, modern supply chain networks require accuracy, transparency, and reliability to be successful.

Core Activities in Modern Supply Chain Management

- Planning and Strategy Formulation: This involves strategic and operational planning to meet customer demands efficiently. Within this we see the emergence of new technologies like artificial intelligence (AI) accurately predicting demand and inventory needs.

- Sourcing: Selecting suppliers and managing pricing and payment processes.

- Transformation: The manufacturing or production stage converts raw materials into finished products. This is where the actual product is created as inventory.

- Delivery:After production, the products need to be delivered to wholesalers, retailers, or directly to consumers. Ensuring products reach customers efficiently, from warehouse to last-mile.

- Handling Customer Complaints: Addressing issues, maintaining customer satisfaction, and managing return rates. Sometimes, things don't go as planned. Managing returns is also an integral part of the supply chain.

Key Themes Throughout the Supply Chain

- Process: One of the biggest challenges the industry faces is creating a seamless process for the supply chain operations. This process begins before the product is even created from deciding the manufacturing, to warehouses receiving the product, all the way through to the order fulfillment. Each element of the process must go smoothly, having visibility throughout the supply chain is essential for this.

- People: At the core of supply chain management are people. Throughout the process from consumer to c-level executive to seamstress there are always people behind the process just getting the product to the last-mile. The general main participants are producers, distributors, retailers, and consumers.

- Integrations: Supply chain integration aims to create one system that unifies stakeholders resulting in enhanced productivity and reducing costs. This approach streamlines the journey from raw materials to final products, minimizing delays, cost hikes, and customer dissatisfaction. By integrating the supply chain into a Collaborative Visibility Platform, organizations achieve transparency and efficiency across all stages, from suppliers to consumers.

- Operations: Operations encompass the design, planning, execution, control, and monitoring of supply chain activities. It is vital for businesses as it involves actions needed to produce goods and services. It manages the flow of resources, data, and finances across the entire value chain, from suppliers to customers.

- Execution: This concentrates on practical applications such as warehouse management systems (WMSs), transportation management systems (TMSs), global trade management (GTM) systems, and other tools like real-time decision support systems (e.g., dynamic routing and sourcing) and supply chain visibility systems.

The Future: Trends and Innovations

Looking ahead, the supply chain industry is poised for exciting changes. Here's what we can expect:

- Increased Digitization: Technologies like IoT, AI, and blockchain will further revolutionize supply chain management. Digitization will increase visibility and efficiency, enable decision support, and reduce costs. According to a 2023 study 89% of companies are planning to or have already adopted a digital first business strategy.

- Sustainability Focus: There's a growing emphasis on eco-friendly practices, from sourcing to delivery. Collaborative efforts with suppliers on green supply chain management initiatives have shown to directly impact environmental practices, highlighting the shift towards eco-friendly practices in the supply chain.

- Greater Collaboration: Enhanced cooperation between different players in the supply chain will become more crucial. Trust throughout the supply chain is absolutely essential,and when it comes to connectivity a Collaborative Visibility Platform is key.

- Customization and Personalization: As customer demands evolve, supply chains will need to adapt to provide more personalized products and services. They are driving changes in supply chain management, influencing aspects like demand forecasting, product development, and sourcing decisions. Consumer preferences are shaping sourcing and supplier relationships, and sustainability concerns are driving eco-friendly practices.

Key Principles

Modern supply chain management is guided by principles like customer focus, collaboration, flexibility, technology utilization, and value creation. These principles ensure that supply chains are efficient, responsive, and able to meet the dynamic needs of the market.

Key Terms

One of the trickiest parts of learning a new industry is getting familiar with the terminology. Here are some of the most important ones to know to sound just like an expert!

- Logistics: Manages goods storage and transport within the supply chain, ensuring timely product movement and efficient use of resources, covering demand planning and inventory management.

- Visibility: Monitoring the entire supply chain for efficient operation and inventory management, enhancing operational efficiency by tracking product status and location.

- Supply Chain Integration: Strategy for streamlining raw material to product flow, reducing delays and costs, and ensuring supply chain transparency and efficiency.

- Warehouse Management Systems (WMS): Software overseeing warehouse activities, crucial for real-time inventory insight and includes features for inventory control, resource management, and analytics.

- Distributor Management Systems (DMS): Vital for consumer goods companies, streamlining supply chain from production to distribution, and enhancing efficiency with real-time data.

- Third-Party Logistics (3PL): Outsourcing storage, logistics, and management to specialists, offering warehousing and transportation services to improve efficiency and market reach.

- Last-Mile: The crucial final step in delivery, often complex and costly, pivotal for e-commerce and retail logistics.

- Economic Order Quantity (EOQ): Ideal order size balancing demand with associated costs, effective under stable demand and cost conditions.

- Backorder: Occurs when out-of-stock items are still in production or available from distributors, indicating higher demand than supply.

- First In First Out (FIFO): Strategy where older stock is sold before newly received goods, prioritizing older inventory in sales.

- Waybill: Legal document and receipt for goods transport, detailing shipment specifics, including origin, destination, and shipping details.

- Electronic Data Interchange (EDI): Digital system for standardized business document exchange, reducing manual errors and enhancing supply chain efficiency.

- Landed Cost: Total cost of a product or shipment, including all associated expenses from production to delivery, crucial for pricing and profitability decisions.

Challenges and Opportunities

Managing a supply chain is no small feat. It involves dealing with complexities like global operations, managing supplier relationships, ensuring quality, and adapting to changing market conditions. The continued growth of e-commerce and multi-channel fulfillment has added another layer of complexity to SCM, requiring businesses to be more agile and customer-focused.

As with any evolving industry, there are challenges, such as managing complex global networks and adapting to technological changes. However, these also present opportunities for innovation and growth.

From its simple beginnings to the complex global networks of today, the supply chain industry has undergone a remarkable transformation. As we look to the future, it's clear that this evolution is far from over. The supply chain industry will continue to adapt, innovate, and thrive in the face of new challenges and opportunities.