4 min read

Mastering Supply Chain: The Crucial Role of Inventory Forecast

Chelsea Mori

:

November 2, 2023

Chelsea Mori

:

November 2, 2023

-1.jpg)

Staying ahead of the curve is not just an advantage; it's a necessity. This is especially important for supply chains. The flow of goods from manufacturers to consumers is a delicate dance that relies on precision, planning, and anticipation. And when it comes to anticipation, nothing holds more weight than a well-crafted inventory forecast.

For brands and retailers, inventory forecasts play a pivotal role in shaping a company's destiny. On the flip side, third-party logistics providers (3PLs) must keep everything moving and have the responsibility of managing and optimizing the supply chains of countless businesses.

The importance of an inventory forecast is indispensable and can be key to survival in a competitive landscape. In this blog, we’ll explore how to unlock excellence in the world of logistics with use of inventory forecast leading practices.

The Inventory Forecast: More Than Just a Number

Imagine trying to navigate a ship through treacherous waters without a map or compass. Now picture running a supply chain without an inventory forecast. It's a risky endeavor, to say the least. Inventory forecasts provide the roadmap, the compass, and the guiding star for businesses, helping them anticipate market trends, customer demands, and stock replenishment needs.

It's not just about predicting how much stock you need, but also when you need it. Accurate forecasts allow your business to align resources, make informed decisions, and optimize inventory levels. This isn't merely about minimizing costs or maximizing profit; it's about delivering what your customers want when they want it, ensuring satisfaction, and building loyalty.

Customer Satisfaction Starts with Inventory Forecasting

One of the primary goals of any retailer is to satisfy customers' needs and wants. But how can you satisfy your customers if you don't even know what they want? Inventory forecasting holds the answer to this dilemma. It enables brands to peer into the future and anticipate consumer trends, enabling them to align their inventory with customer demand accurately.

When you can predict what products your customers will be seeking, you can work with your 3PLs and partners to help keep inventory available with precision, ensuring that customers find what they need, precisely when they need it.

A Crystal Ball for Operational Efficiency

Supply chain professionals may not be magicians, but they do possess a unique power: the ability to foresee the future. This is especially true if you have collaborative technology that offers visibility throughout the entire supply chain and can forecast inventory like a crystal ball. For efficient operations, brands require predictive insights that help them reduce overstocks, minimize waste, and boost efficiency. Here's how it works:

Demand Forecasting:

Knowing what products will be in demand and when allows you to stock up on popular items and avoid overstocking the shelves with slow-moving goods. Accurate forecasting can prevent costly fees for storage or holding costs.

Optimized Inventory Management:

Proper inventory forecasts help you maintain the right balance between carrying costs and stockouts, ensuring you always have what your customers need. Stockouts on popular inventory can potentially be detrimental for your business.

Strategic Decision-Making:

Inventory forecasts give you the insights needed to make crucial decisions like expansion, procurement, and risk management. It can also help retailers make more informed decisions about resource allocation and even product placement.

Streamlining Efficient Logistics

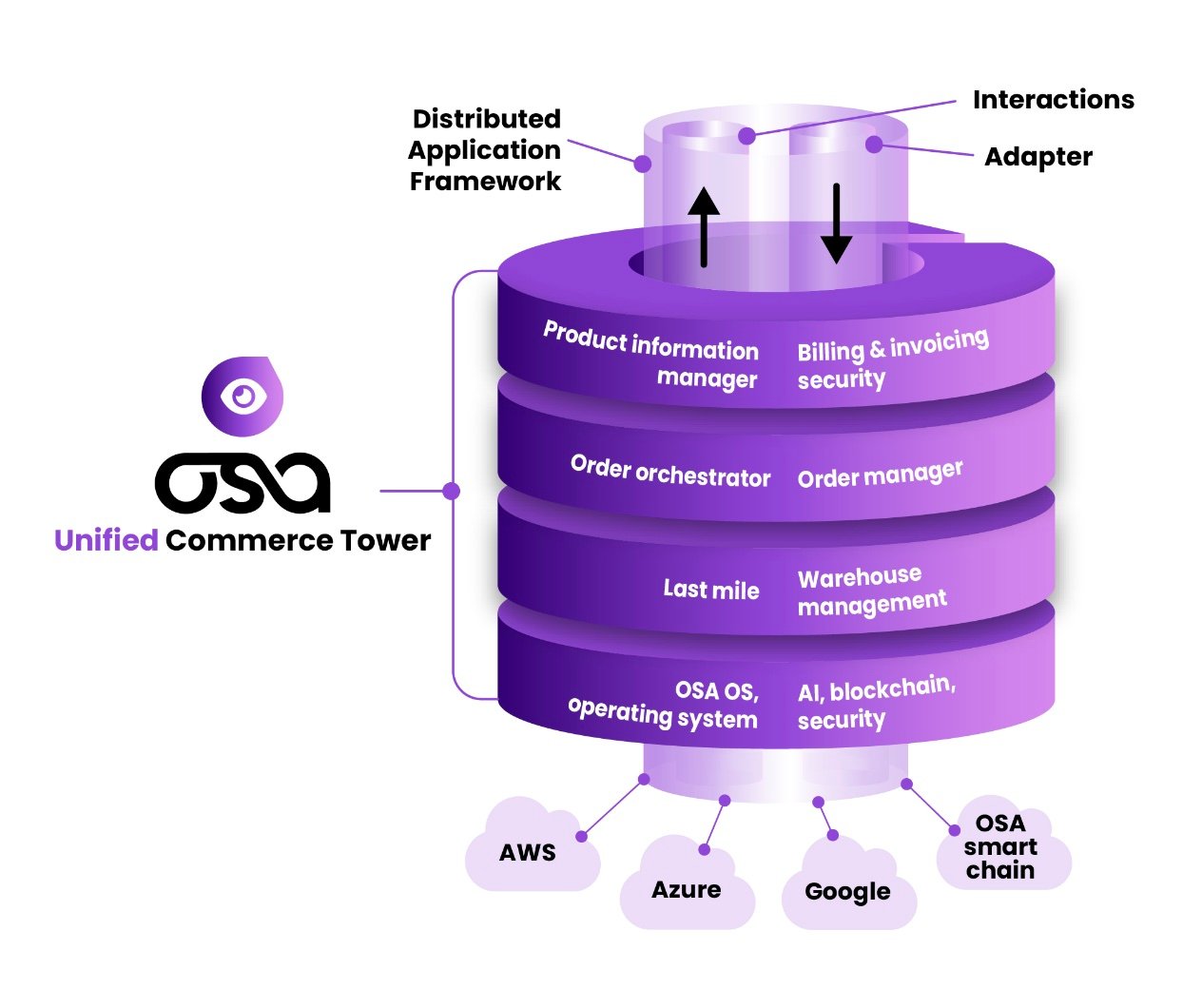

Logistics partners, especially 3PLs, must have the foresight to enable their customers to have flexibility in shifting marketplaces and shipping demands. Market dynamics, consumer preferences and external factors can impact supply chain decisions—especially inventory forecasts. 3PLs require supply chain technology that integrates with demand channels and order management software (OMS), warehouse management systems (WMS), and transportation and last mile providers, just to name a few.

Optimize Inventory Levels:

Precise forecasts help 3PLs maintain optimal inventory levels, minimizing costs associated with excess storage and ensuring there's always enough stock on hand for their brand and retail customers.

Ensure Timely Deliveries:

Anticipating demand enables 3PLs to make sure goods are in the right place at the right time, which is the essence of logistics success and customer satisfaction.

Efficient Resource Allocation: Knowing what's coming down the pipeline allows 3PLs to allocate resources strategically, from personnel to transportation, for maximum efficiency.

Building Resilience and Responsive Retail

With the right forecasting tools and methodologies, brands and retailers can adjust their strategies in real time, keeping their inventory in sync with market dynamics. This adaptability is the hallmark of a successful supply chain. By analyzing trends and data, supply chains can adapt forecasts to accommodate shifting conditions. This agility can help businesses stay ahead of the competition and respond to unforeseen challenges with confidence.

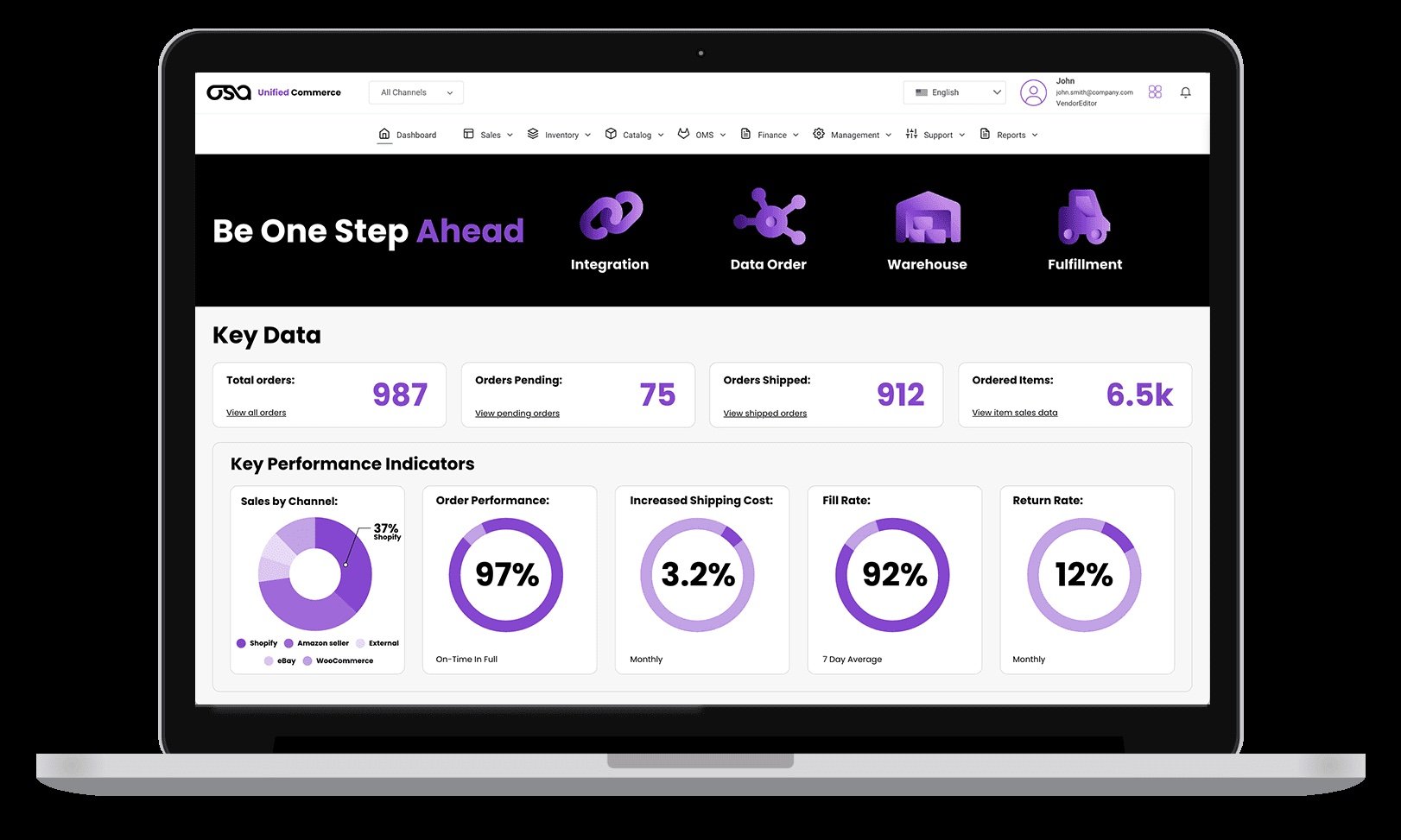

As supply chains grow more and more complex, companies must modernize for forecasting demands and inventory planning. Today’s platforms offer sophisticated algorithms, predictive analytics utilizing artificial intelligence (AI), and innovative integrations to help simplify inventory forecasting. This data helps supply chain professionals by offering context to pair with their strong industry knowledge.

Logistics partners, shippers, and 3PLs also bring cutting-edge forecasting tools and software with the wisdom and intuition of seasoned experts. It's the synergy of these elements that results in accurate, actionable forecasts that drive excellence.

.jpg?width=1080&height=1080&name=carousel%20(1).jpg)

Empower Your Business with Inventory Forecasting

Inventory forecasting isn't a luxury; it's a necessity in today's supply chain landscape. It's about more than numbers and predictions; it's about making sure you have the right product, in the right place, at the right time. It's about building a resilient, responsive supply chain that not only satisfies your customers but also sets you apart in the competitive marketplace.

Building a strong forecasting team, equipped with both the latest technology and a deep understanding of your industry, is the key to making your supply chain unbeatable. It isn’t just about crunching numbers; it's about understanding the subtleties of the market and leveraging data to make informed decisions, optimize operations, and remain competitive in a challenging market.

So, if you're not already harnessing the power of inventory forecasting, it's time to get started. Embrace the insights it offers, and you'll find your supply chain running smoother, your customers happier, and your business thriving in an ever-changing world. In this game of supply chain mastery, the best players are those who can anticipate the moves before they happen.