Welcome back to class! In our first course, Supply Chain 101, we touched on the basics and history of the supply chain industry. We are now going to be covering more advanced supply chain topics in this course, Supply Chain 102.

Explore the intricacies and key terms of advanced supply chain topics and delve into the fascinating history of supply chain management with Osa Commerce.

Table of Contents

Evolution of Supply Chain Management

Advanced Supply Chain Strategies

Key Terms to Know to be an Expert in the Supply Chain Industry

Important Technologies in Modern Supply Chains

Sustainability in Supply Chain

Challenges and Opportunities in Supply Chains

Evolution of Supply Chain Management

The evolution of supply chain management can be traced back to the early 20th century when businesses began to realize the importance of managing the flow of goods and materials from suppliers to customers. Initially, supply chain management focused on improving efficiency and reducing costs through practices like just-in-time inventory management and lean manufacturing.

As technology advanced and globalization became more prevalent, supply chain management had to adapt to new challenges. The rise of the internet and e-commerce in the late 20th century revolutionized supply chain practices, enabling real-time tracking of shipments and improved communication between suppliers, manufacturers, and retailers.

Today, supply chain management continues to evolve with the integration of emerging technologies like artificial intelligence (AI), blockchain, and The Internet of Things (IoT). These technologies enabling greater visibility, efficiency, and collaboration throughout the supply chain, leading to improved customer satisfaction and business performance.

Advanced Supply Chain Strategies

Advanced supply chain strategies involve the implementation of innovative approaches to enhance the performance and competitiveness of a supply chain. These strategies focus on optimizing various aspects of the supply chain, including inventory management, order fulfillment, transportation, and customer service.

One advanced supply chain strategy is demand-driven planning, which aims to align production and inventory levels with customer demand in real-time. By utilizing advanced analytics and forecasting techniques, companies can better anticipate customer demand and adjust their supply chain operations accordingly.

Another advanced strategy is vendor-managed inventory (VMI), where the supplier takes responsibility for managing the inventory levels at the customer's location. This approach improves inventory visibility, reduces stockouts, and minimizes carrying costs for both the supplier and the customer.

Collaborative planning, forecasting, and replenishment (CPFR) is another advanced supply chain strategy that involves sharing information and collaborating closely with key partners in the supply chain. By sharing data and jointly developing forecasts, companies can improve demand planning accuracy, reduce lead times, and enhance overall supply chain efficiency.

These are just a few examples of the many advanced supply chain strategies available to companies today. Each strategy offers unique benefits and challenges, and the choice of strategy depends on the specific needs and goals of the organization.

Key Terms to Know to be an Expert in the Supply Chain Industry

To become an expert in the supply chain industry, it is essential to be familiar with key terms and concepts. Here are some important terms to know:

- Lean Manufacturing: A systematic approach to eliminating waste and improving efficiency in the manufacturing process.

- Electronic Data Interchange (EDI): This facilitates seamless data transfer between computer systems by standardizing information formats. Widely used in scenarios where paper-based exchanges occur, such as sending invoices or orders from a seller to a logistics provider.

- Cross Docking: A logistics strategy where incoming goods from suppliers are unloaded from inbound vehicles and directly loaded onto outbound vehicles with little to no storage time in between. This process minimizes inventory holding costs and reduces handling time, enabling efficient distribution of goods from suppliers to customers.

.jpg?width=1280&height=720&name=Blog%20covers%20(67).jpg)

- Pipeline Inventory: These are goods in transit within the supply chain, spanning from suppliers to warehouses, between warehouses, or from warehouses to retailers. These goods are not yet available for sale or use but play a critical role in ensuring timely deliveries and maintaining optimal stock levels throughout the supply chain.

- Application Programming Interface (API): These are integrations that link applications, facilitating data sharing through programmed software forms. They automate data syncing, enhancing visibility, accuracy, and efficiency by seamlessly connecting separate systems within a company.

- Drop Shipment: This is when a buyer's vendor holds title to products without handling, stocking, or delivering them—like when one supplier ships directly to another or to the buyer's customer—it's a convenient way to sell slow-moving items with a long product life, avoiding storage and maintenance costs.

- Distributed Order Management (DOM): An advanced inventory and order management system that is networked to automatically select and route orders to the best fulfillment location using rules-based decisions, eliminating the need for manual intervention. Basically a more personalized Order Management System (OMS).

- Omnichannel: This fulfillment method harmonizes sales channels for a seamless customer journey, from order to delivery. Effective strategies consolidate operational processes like order processing from multiple marketplaces, e-commerce platforms, or physical stores. Retailers leveraging third-party logistics (3PL) can enhance flexibility and visibility by accessing inventory from any channel or location. Omnichannel fulfillment essentially creates the same processes across all selling channels ensuring consistency for all customers.

- Advanced Shipping Notice (ASN): A pre-delivery notification commonly transmitted electronically through EDI. Buyers often request it as part of their trading or EDI standards. It's sent ahead of shipment from a supplier or third-party logistics provider to enhance goods receiving efficiency.

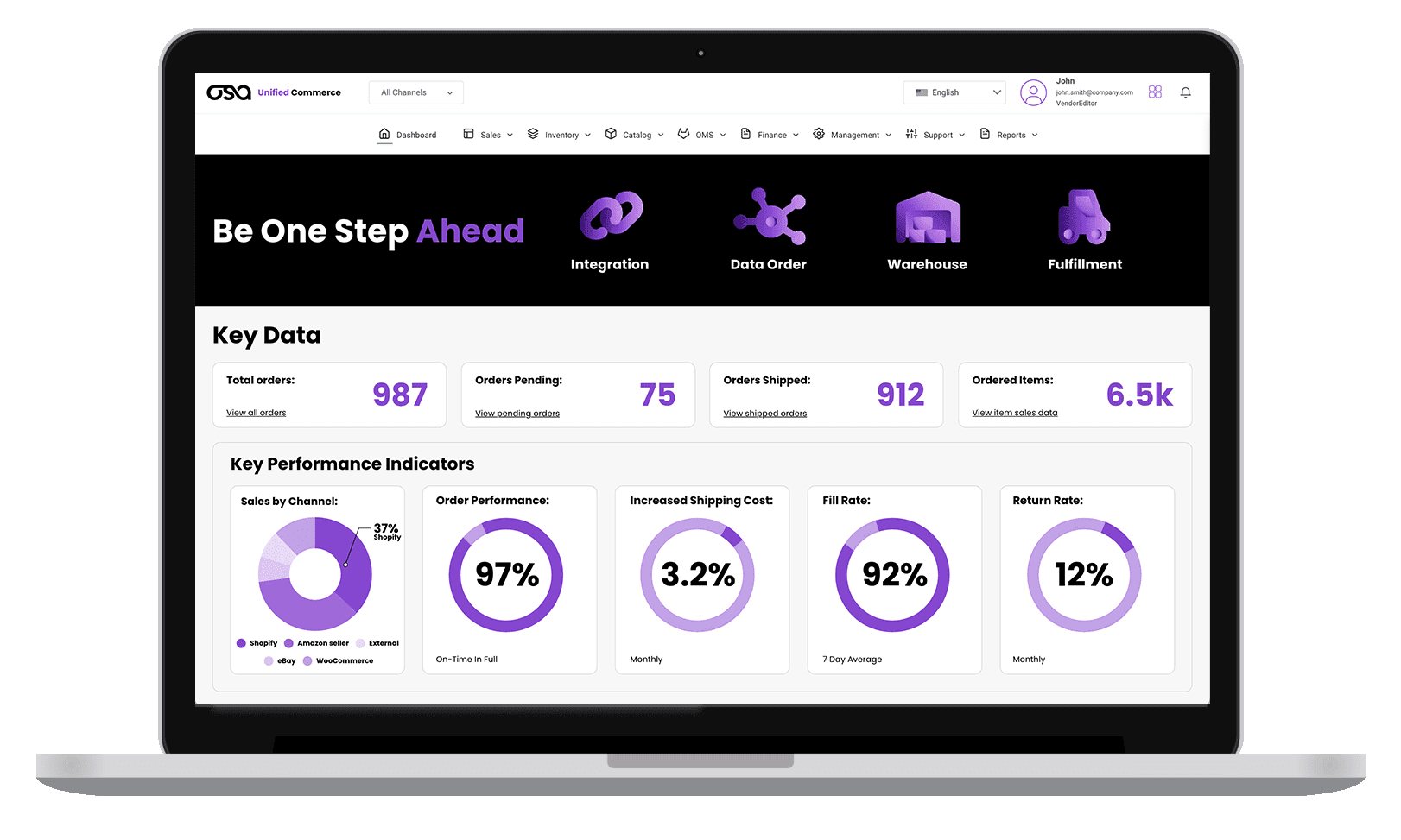

- Unified Commerce: This addresses retail disruptions by integrating front-end and back-end systems into a single platform, merging omnichannel and multichannel approaches. This consolidation offers brands a unified view of sales, networks, and inventory across digital and physical channels. It also provides merchants with a comprehensive view of customer behavior across all touchpoints, enabling consistent shopping experiences through agile technology.

- Enterprise Resource Planning (ERP): This integrates essential business functions like accounting, HR, procurement, supply chain, and CRM into a centralized database. It offers a comprehensive view of organizational activities, enabling performance monitoring, resource tracking, and workflow optimization. Customizable modules enhance communication and collaboration across departments, boosting productivity and supporting business growth. Check out why we think a WMS is the better option for supply chains.

- Stockout: This happens when a business exhausts its supply of a product. This prevents customers from ordering it, forcing the business to update its availability status. Accepting orders for out-of-stock items can lead to customer disappointment or increased costs for rush production and shipping to fulfill orders promptly.

- Inventory Forecasting: Also known as demand planning, predicts future inventory needs using past data, trends, and upcoming events. It ensures businesses meet customer orders without excess inventory tying up cash. It involves data analysis to adapt to changing conditions and meet customer demand effectively.

- Collaborative Visibility: Create a comprehensive network utilizing tech-agnostic solutions that offer real-time data sharing data-driven insights to enhance overall efficiency and transparency across your entire supply chain.

By understanding and applying these key terms, professionals can effectively navigate the complexities of the supply chain industry and make informed decisions to optimize their operations.

Important Technologies in Modern Supply Chains

Modern supply chains are leveraging various technologies to enhance efficiency, visibility, and collaboration. Some important technologies in modern supply chains include:

- Artificial intelligence (AI): AI-powered systems can analyze vast amounts of data, identify patterns, and make predictions to optimize supply chain operations. This includes demand forecasting, route optimization, and inventory management.

- Internet of Things (IoT): IoT devices, such as sensors and RFID tags, enable real-time tracking and monitoring of goods throughout the supply chain. This improves visibility, reduces the risk of loss or theft, and enhances inventory accuracy.

- Blockchain: Blockchain technology provides a secure and transparent platform for recording and verifying transactions across the supply chain. It improves traceability, reduces fraud, and enhances trust between supply chain partners.

- Robotic Process Automation (RPA): RPA involves the use of software robots to automate repetitive and manual tasks in the supply chain, such as data entry and order processing. This improves efficiency, reduces errors, and frees up human resources for more strategic activities.

- Cloud Computing: Cloud-based platforms enable real-time collaboration and data sharing among supply chain partners. This enhances communication, streamlines processes, and facilitates data-driven decision-making.

- Tech Agnostic: In the supply chain this refers to a strategy or approach that is not biased towards any specific technology or platform. It means being open to utilizing various technological solutions and systems, regardless of their origin or brand, to optimize processes and achieve objectives within the supply chain.

These technologies are revolutionizing supply chain management by enabling greater agility, visibility, and responsiveness. Organizations that embrace these technologies gain a competitive advantage in today's fast-paced and complex business environment.

Sustainability in the Supply Chain

Sustainability is an increasingly important aspect of supply chain management, as businesses strive to reduce their environmental impact and operate in a socially responsible manner. Here are some key points about sustainability in the supply chain:

- Green Logistics: Adopting eco-friendly practices in transportation, such as using electric vehicles or optimizing delivery routes to minimize fuel consumption and emissions.

- Sustainable Sourcing: Ensuring that raw materials and components are ethically and responsibly sourced, considering factors such as fair trade, labor conditions, and environmental impact.

- Waste Reduction: Implementing strategies to minimize waste generation and promote recycling and reuse throughout the supply chain.

- Carbon Footprint Reduction: Taking steps to measure, manage, and reduce greenhouse gas emissions associated with supply chain activities.

- Social Responsibility: Upholding ethical standards and promoting fair labor practices across the supply chain, including suppliers and subcontractors.

By integrating sustainability into their supply chain practices, companies can not only contribute to a more sustainable future but also gain a competitive advantage by meeting the growing demand for environmentally and socially responsible products and services.

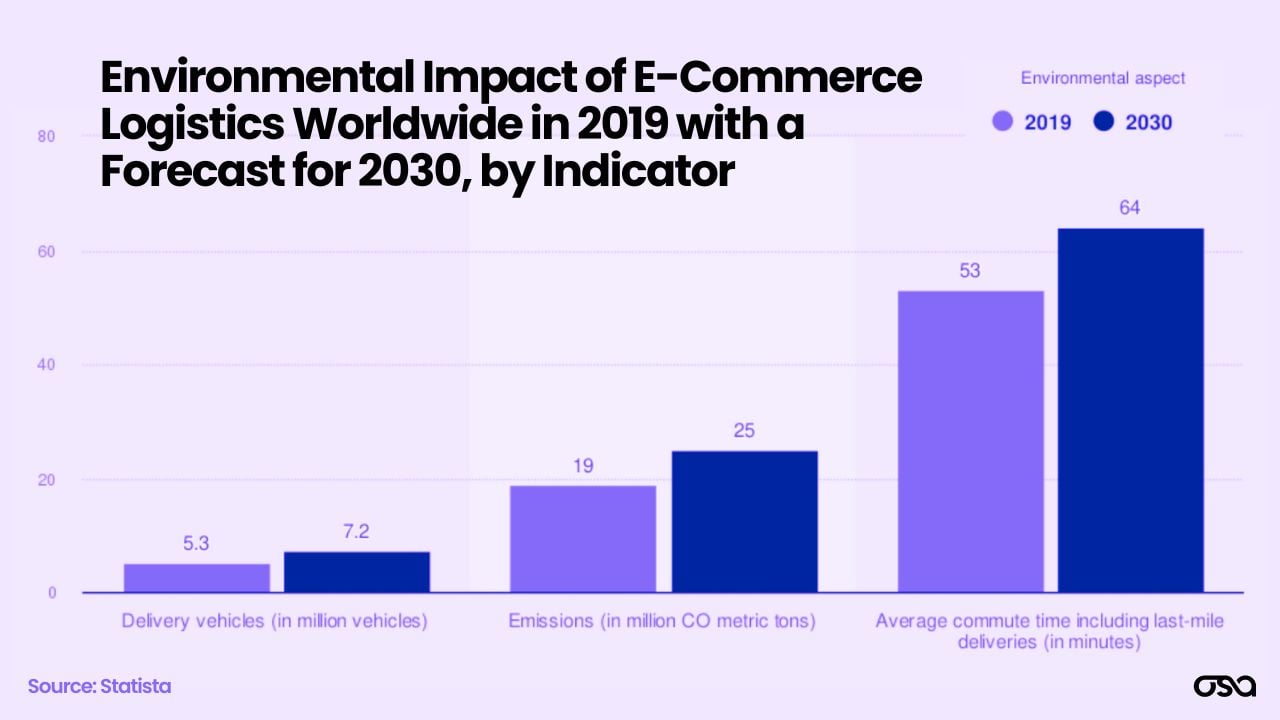

By 2030, e-commerce logistics are projected to generate approximately 25 million CO2 metric tons in carbon emissions. E-commerce retailers will face the dual challenge of greening their supply chains while meeting the demands of consumers who seek both fast and affordable delivery options.

Challenges and Opportunities in Global Supply Chains

Global supply chains present both challenges and opportunities for businesses. Here are some key points to consider:

- Complexity: Global supply chains involve multiple stakeholders, languages, currencies, and regulations, making coordination and communication more complex. However, they also offer access to a wider range of markets and resources.

- Risk Management: Operating in different countries and regions exposes businesses to various risks, such as political instability, natural disasters, and trade disputes. Effective risk management strategies are crucial to mitigate these risks.

- Cultural Differences: Cultural nuances and business practices vary across countries, requiring businesses to adapt and understand local customs to build successful relationships with suppliers, partners, and customers.

- Market Demand: Global supply chains allow businesses to tap into new markets and cater to diverse customer demands. However, understanding and adapting to local preferences and market trends is essential for success.

- Supply Chain Resilience: Global disruptions, such as the COVID-19 pandemic, have highlighted the importance of building resilient supply chains. This involves diversifying suppliers, enhancing visibility, and implementing contingency plans.

While global supply chains pose challenges, they also offer immense opportunities for growth and expansion. By understanding and effectively managing these challenges, businesses can leverage the advantages of global supply chains and thrive in the global marketplace.

Congratulations, you aced the class!

If you'd like to brush up on some of your knowledge check out our first blog of the series, Supply Chain 101, where we get into the absolute key base knowledge of supply chains, from history to key terms!

Osa Commerce Launches AI-Powered Retail Compliance at Manifest 2026, Targeting $5 Billion Chargeback Problem

Why Unified Commerce Integration Is the Foundation of Scalable Supply Chains

.jpg)

Standing At The Crossroads: The Dawn Of Agentic Commerce

Katie Dalrymple

Katie Dalrymple