Discover how automation is revolutionizing modern supply chains, enhancing efficiency, and streamlining operations in ways that go beyond traditional robotics. Supply chain automation now encompasses a broad spectrum of innovative solutions. From collaborative visibility technology to warehouse management system (WMS) workflow automation and EDI or API integrations, businesses must leverage cutting-edge tools to optimize processes, reduce manual intervention, and meet the increasing demands of a complex industry. The evolution of automation in supply chains is paving the way for enhanced productivity, accuracy, and competitiveness.

Exploring the Broad Spectrum of Automation in Supply Chains

Automation has become a cornerstone of modern supply chain management. Collaborative Visibility Technology is at the front of this revolution, offering innovative solutions that go beyond traditional physical automation. While robotics has played a crucial role in transforming supply chains, automation now encompasses a much broader spectrum, from streamlining workflows to integrating various systems seamlessly.

The need for automation has never been more critical. As supply chains grow more complex, the demand for faster, more efficient processes has intensified. Automation helps meet these demands by reducing manual intervention, minimizing errors, and speeding up operations. This multifaceted approach to automation is essential for businesses striving to stay competitive in a rapidly evolving market.

Collaborative Visibility Is Closer Than You Think

Level up your supply chain with a platform that pays for itself—it's that simple. Connect Everything, Amplify Visibility, Predict the Future.

Enhancing Efficiency with Workflow Automation

While physical automation addresses the tangible aspects of supply chain operations, workflow automation targets the intangible processes. By automating workflows, businesses can streamline their operations, reduce manual intervention, and increase overall efficiency.

Workflow automation involves using software tools to manage and automate various tasks, such as order processing, inventory management, and customer communications. This not only speeds up processes but also ensures consistency and accuracy, leading to improved service levels and customer satisfaction.

Types of Supply Chain Automation

There are several types of automation that can be implemented in supply chains to improve efficiency, accuracy, and speed. These include:

Physical Automation

Robotics:

Automated systems such as robotic arms for picking, packing, and sorting goods in warehouses, have revolutionized the efficiency and accuracy of supply chain operations. These robotic systems are equipped with advanced technology to handle repetitive tasks with precision and speed, significantly reducing the risk of human error. By implementing robotics in warehouses and distribution centers, businesses can achieve higher throughput, lower labor costs, and ultimately improve their bottom line.

Workflow Automation

Order Processing:

Automating order entry, processing, and tracking to reduce manual input and errors is a game-changer in modern supply chains. By implementing advanced software solutions, businesses can streamline the entire order processing workflow, from the moment an order is placed to its fulfillment. Automation not only speeds up processing times, but it also guarantees precision and uniformity, ultimately enhancing customer satisfaction and loyalty. This efficient method not only reduces room for error but also maximizes resource efficiency, driving businesses toward exceptional success.

Inventory Management:

Automated systems for real-time inventory tracking, reordering, and stock-level optimization are crucial components of a well-functioning supply chain. With the help of cutting-edge technology, businesses can gain real-time visibility into their inventory levels, track product movements, and automate the replenishment process. By optimizing stock levels and reducing the risk of stockouts or overstocking, companies can minimize carrying costs and maximize operational efficiency. This proactive approach to inventory management enables businesses to meet customer demands effectively and stay one step ahead of the competition.

.jpg)

Back From Manifest 2026: Visibility, Collaboration & The Next Supply Chain Operating Model

Osa Commerce Launches AI-Powered Retail Compliance at Manifest 2026, Targeting $5 Billion Chargeback Problem

Why Unified Commerce Integration Is the Foundation of Scalable Supply Chains

Rate Shopping Automation

Another critical area is where software tools automatically compare shipping rates from various carriers to find the most cost-effective options. This not only saves time but also reduces shipping costs, benefiting both businesses and customers. Let's break it down.

Shipping Rate Optimization:

Automated tools compare shipping rates across carriers to find the most cost-effective option, reducing costs and improving supply chain efficiency. Utilizing advanced algorithms and real-time data analysis, these tools evaluate multiple shipping options based on factors like weight, destination, and delivery time. This saves time for logistics managers and ensures businesses choose the most efficient shipping method for each shipment, helping them stay competitive by offering lower shipping fees to customers. Additionally, these tools provide insights on shipping trends and performance metrics, allowing businesses to optimize strategies and improve overall supply chain operations.

Freight Management:

Automating freight management optimizes carrier selection, route planning, and real-time tracking, leading to faster deliveries and lower costs. By analyzing data and traffic conditions, businesses identify efficient routes and improve communication. This automation provides valuable insights for optimization, enabling informed decisions, adaptation to market changes, and increased supply chain efficiency.

Integration Automation

Enterprise Resource Planning (ERP) and Warehouse Management System (WMS):

These integrations streamline supply chain operations by connecting systems, ensuring seamless data flow, real-time updates, and improved decision-making.

An Enterprise Resource Planning (ERP) system integrates various business functions like accounting, human resources, procurement, and customer management, providing a comprehensive view. It essentially serves as a comprehensive toolbox of business applications.

In contrast, a Warehouse Management System (WMS) is specialized software for efficient warehouse and supply chain operations. stands as a sophisticated software solution that forms the backbone and foundation of supply chain operations. Originally designed for third-party logistics (3PL) warehouses, today's supply chain businesses, including fourth-party logistics (4PL), brands, and retailers, utilize WMS platforms to optimize and manage operations within a warehouse. Going beyond ERP systems and basic inventory tracking, WMS functionalities encompass a wide array of essential tasks for efficient warehouse and holistic supply chain operations.

These both optimize resource utilization, enhance inventory management, and enable efficient order fulfillment. Opting for a WMS in 3PL operations ensures dynamic warehouses ready for growth and technological advancements, offering tailored functions for inventory, order fulfillment, and logistics. Investing in a WMS aligns current and future warehouse needs, supporting growth and innovation for sustained success.

Transport Management System (TMS):

Integrating TMS into supply chain automation provides real-time visibility, optimizes route planning, and enhances delivery performance. This seamless communication between stakeholders allows businesses to track shipments, monitor progress, and address disruptions proactively. Incorporating TMS into supply chain automation also allows for better resource optimization and dynamic route adjustments. By utilizing the data and insights provided by TMS, businesses can make informed decisions regarding the allocation of resources, ensuring that deliveries are carried out efficiently and cost-effectively.

Data Analytics and Reporting

Predictive Analytics:

Utilizing cutting-edge automated systems powered by artificial intelligence and machine learning algorithms, businesses can delve deep into their data to uncover patterns, trends, and potential disruptions in the supply chain. By analyzing historical data alongside real-time information, predictive analytics enables proactive decision-making, allowing companies to anticipate demand fluctuations, optimize inventory levels, and mitigate risks before they escalate. This strategic approach not only enhances operational efficiency but also fosters agility and resilience, positioning businesses to stay ahead of the curve.

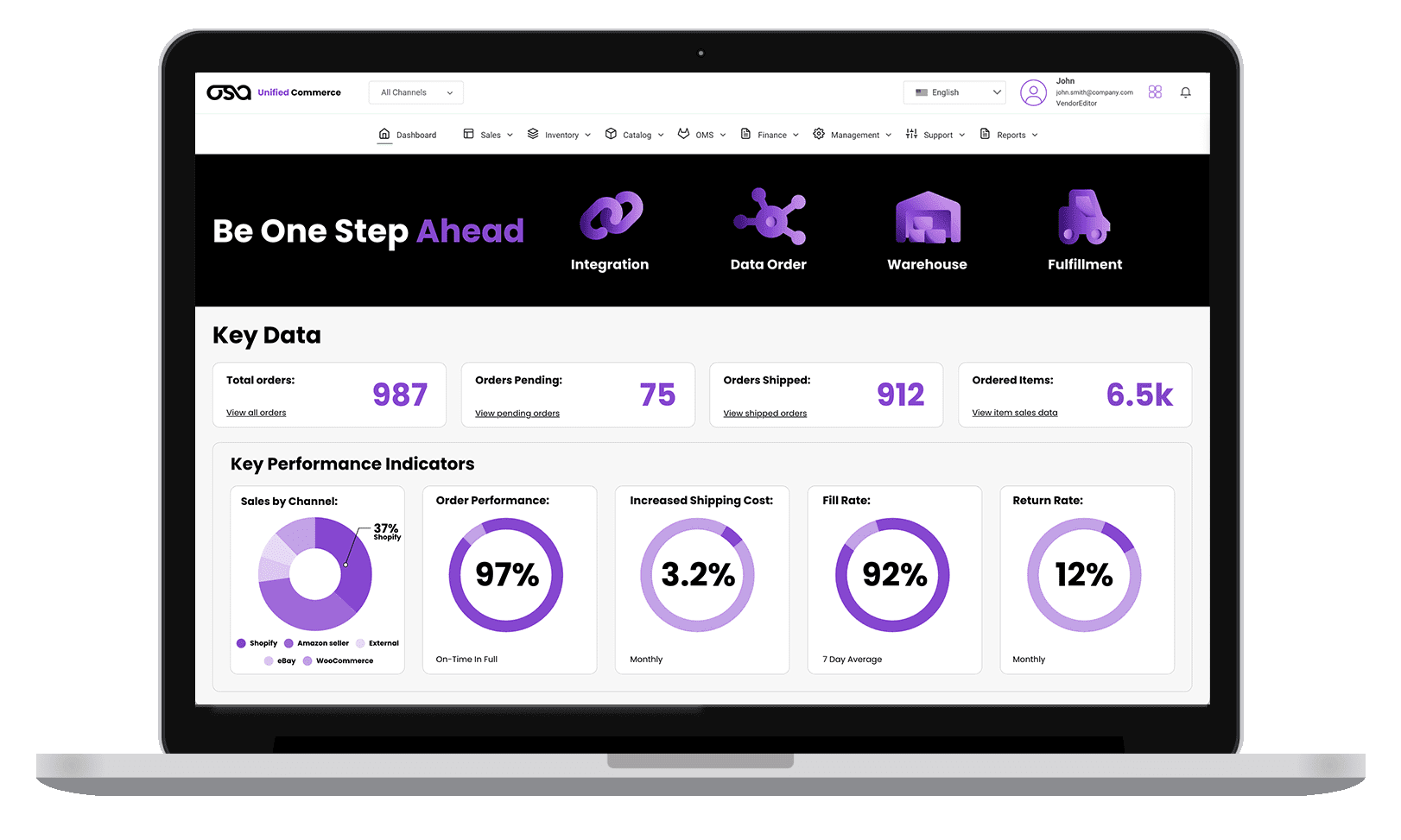

Automated Reporting:

Generating reports on supply chain performance metrics without manual input is a game-changer in modern supply chain management. By leveraging advanced reporting tools and systems, businesses can access real-time data on key performance indicators (KPIs) such as inventory turnover, order fulfillment rates, and shipping costs. This automated process not only saves time but also ensures accuracy and consistency in reporting, allowing companies to make informed decisions and drive continuous improvement in their supply chain operations. Additionally, automated reporting enables stakeholders to easily track progress, identify trends, and optimize strategies for enhanced efficiency.

Customer Communication Automation

Chatbots and Virtual Assistants:

Implementing chatbots and virtual assistants in customer communication automation plays a crucial role in enhancing the overall customer experience. Chatbots are AI-powered tools that can handle a wide range of customer inquiries, from product information to order tracking, in a quick and efficient manner. By automating customer service inquiries, businesses can provide instant responses to customers, improving satisfaction and reducing response times. Virtual assistants, on the other hand, can assist customers with more complex issues, such as returns processing or personalized recommendations. By automating order status updates and returns processing through these intelligent tools, businesses can streamline processes, reduce manual workload, and ensure a seamless customer journey. The integration of chatbots and virtual assistants not only decreases manual workloads but also allows businesses to provide personalized and timely support to their customers, ultimately leading to increased loyalty and retention.

Automated Notifications:

Customers expect real-time updates on their orders, delivery timelines, and any potential delays. By implementing automated notification systems, businesses can keep their customers informed and engaged throughout the entire shopping journey. From order confirmation to dispatch notifications and delivery tracking, these automated messages provide transparency and peace of mind to customers, ensuring a seamless and satisfying shopping experience. With instant updates on order status and delivery progress, businesses can build trust and loyalty with their customers. By prioritizing customer communication through automated notifications, businesses can enhance customer satisfaction, drive repeat purchases, and ultimately boost their bottom line.

Manufacturing Automation

Production Line Automation:

Implementing robots and automated machinery in manufacturing processes to enhance productivity is a game-changer in the industry. By integrating technology and robotics into production lines, businesses can streamline operations, increase efficiency, and improve overall output quality. These automated systems can perform repetitive tasks with precision and consistency, reducing the risk of errors and maximizing throughput. With real-time monitoring and data analytics, manufacturers can optimize production schedules, identify bottlenecks, and make informed decisions to drive continuous improvement. Production line automation not only accelerates manufacturing processes but also enhances safety and reliability, transforming the way products are made and setting new standards for operational excellence.

Quality Control Automation:

Quality control automation ensures products meet high standards through automated inspections using advanced technology like machine vision and sensors. This enhances product quality, boosts operational efficiency, and reduces manual inspection time and resources. Integration of automated systems streamlines quality control, identifies issues in real time, and proactively addresses them, ultimately enhancing the customer experience, building brand trust, and differentiating businesses.

Demand Planning and Forecasting

Automated Forecasting Tools:

Leveraging machine learning algorithms and advanced data analytics to accurately predict demand patterns, optimize inventory levels, and improve supply chain efficiency. By analyzing historical data, market trends, and external factors, these tools enable businesses to forecast demand with precision, allowing for proactive inventory management and strategic decision-making. Through automation, businesses can anticipate fluctuations in customer demand, adjust production schedules, and optimize stock levels to meet customer needs effectively. Leveraging machine learning in forecasting tools empowers businesses to make data-driven decisions, adapt to changing market conditions, and drive continuous improvement.

.jpg)

Back From Manifest 2026: Visibility, Collaboration & The Next Supply Chain Operating Model

Osa Commerce Launches AI-Powered Retail Compliance at Manifest 2026, Targeting $5 Billion Chargeback Problem

Why Unified Commerce Integration Is the Foundation of Scalable Supply Chains

Supply Chain Planning:

Automating the planning of procurement, production, and distribution activities based on demand forecasts is essential. By utilizing advanced technologies and data analytics, automated supply chain planning streamlines the entire process, from identifying suppliers and optimizing production schedules to efficiently distributing products to end customers. This automation improves inventory management, reduces costs, and minimizes the risk of stockouts. By aligning procurement, production, and distribution activities with demand forecasts, businesses can make informed decisions, adapt to market changes, and ultimately drive continuous improvement in their supply chain operations.

Emerging Technologies Transforming Supply Chains

The future of supply chain automation is being shaped by emerging technologies that promise to further enhance efficiency and innovation. Autonomous vehicles, for example, are set to revolutionize transportation and logistics by enabling faster, more reliable deliveries without the need for human drivers.

Other technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain, are also making significant impacts. IoT devices provide real-time visibility into supply chain operations, AI algorithms optimize decision-making processes, and blockchain ensures transparency and security in transactions.

Predicting the Future: Innovations in Supply Chain Automation

As technology continues to evolve, businesses must stay one step ahead to maintain a competitive edge. Continuous innovation in supply chain automation is essential for adapting to changing market demands and achieving long-term success.

By embracing new technologies and integrating them into supply chain processes, businesses can unlock new levels of efficiency, accuracy, and customer satisfaction.

Osa can offer companies the technology and expertise to navigate the complexities that come with incorporating automation and AI into supply chains, driving growth and profitability.

.jpg?width=1280&height=720&name=The%20Role%20of%20Automation%20in%20Modern%20Supply%20Chains%20Image%201%20(final).jpg)